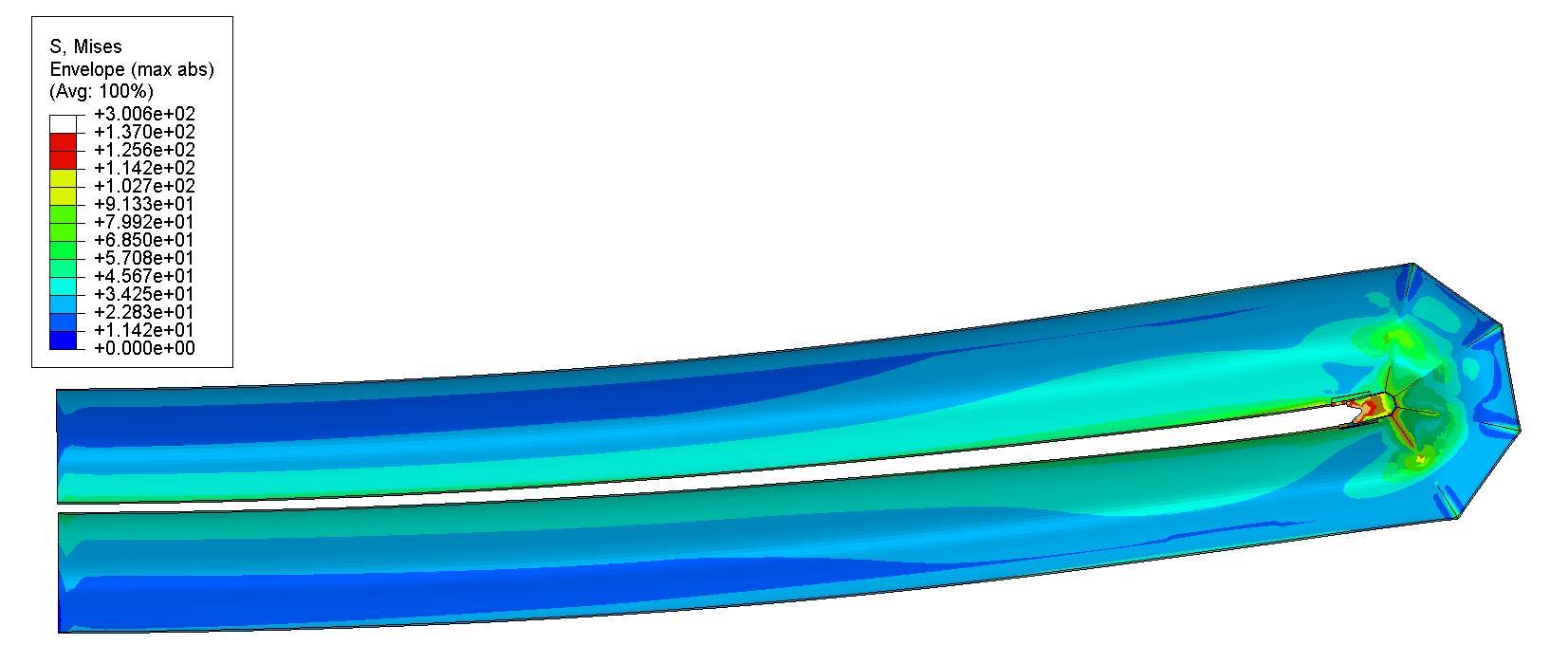

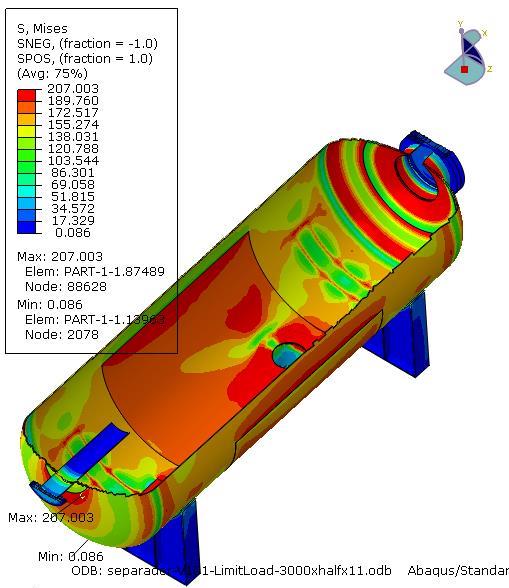

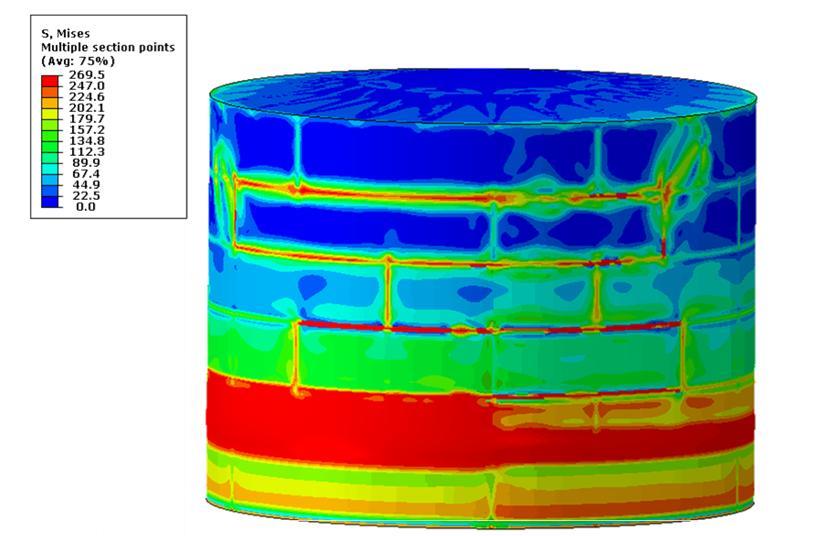

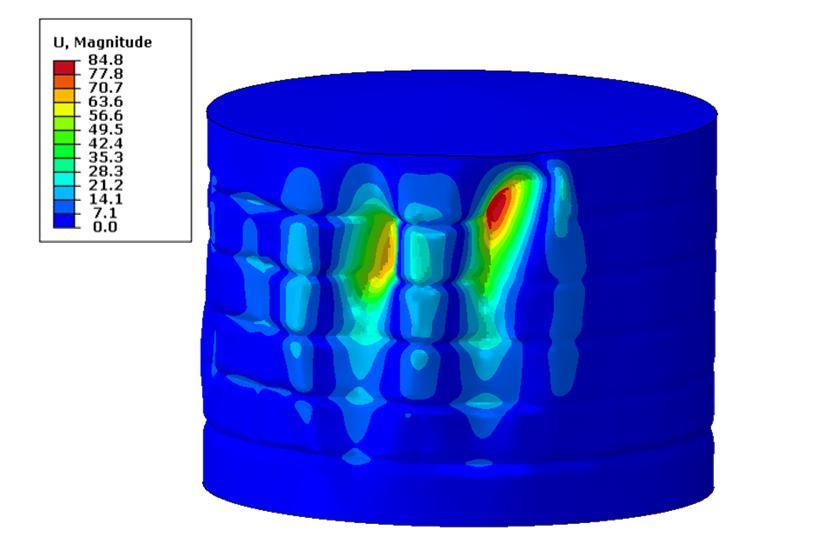

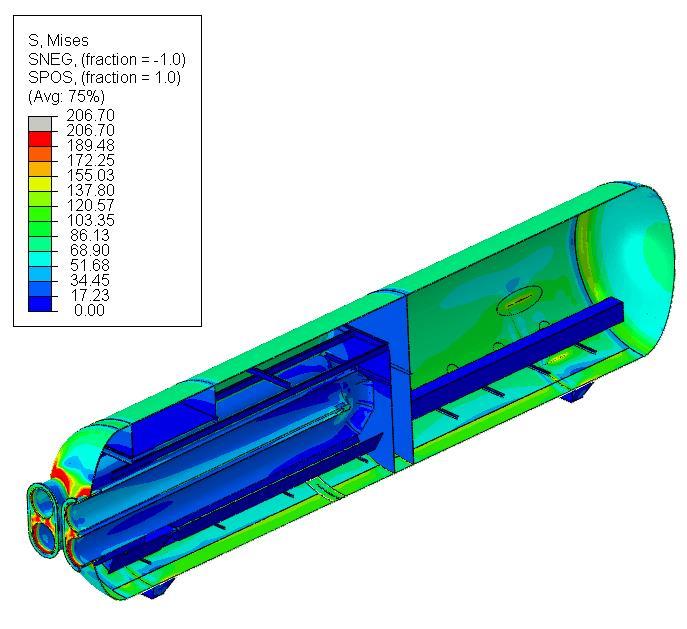

Fitness for Service (FFS) studies of a piece of equipment in which a defect was detected, it has come to the end of its usable life, or is requested to serve outside its design condition are based on surveys, testing and models in order to define whether its components can continue operating or not and/or which ones need repairing or replacing. This service is performed using standardized and technically justified procedures to guarantee consistent and accurate forecasts. FFS techniques include procedures such as those defined in the standard API STD 579 âFitness for Serviceâ. We count with the experts and tools for all testing, both physical and numerical, for the evaluation of the components subjected to: pressure and external loads, which might present volumetric defects (deformation, wear, erosion, corrosion, etc.), planar (fatigue, stress corrosion cracking, lack of fusion or penetration in welds, etc.) and/or microstructural (hydrogen embrittlement, creep, etc.)