API tanks

We implement integral projects of tanks under API 650 norms. We provide basic and detail engineering, memory estimates and 3D models of new facilities. For fitness for service studies, go to section post-failure analysis.

Ver mas

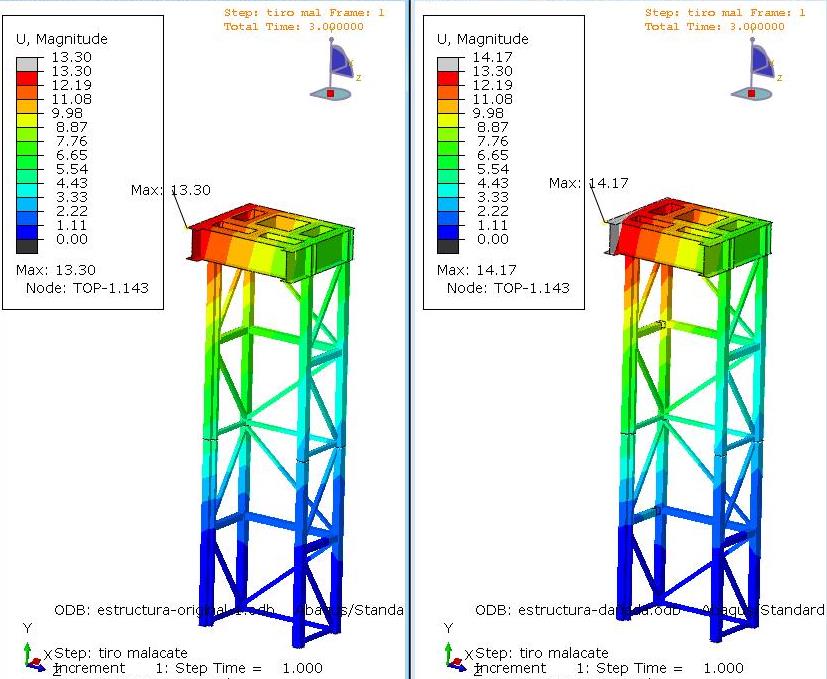

Project and analysis of onshore and offshore structures integrity

We carry out projects for civil or mechanical structures in industrial environments under CIRSOC, ASME or AISC regulations. We provide integrity analysis for damaged structure owing to corrosion, weariness, creep or impact, both in onshore and offshore conditions.

Ver mas The projects of new structures are carried out end to end, providing basic engineering for interaction with the customer, structural estimation and detail engineering. The development of the project is in 3D from its design, using CAD and CAE models with capacity for damage incorporation and relieving implantation areas by means of laser scanning or photometry.

Ver Menos

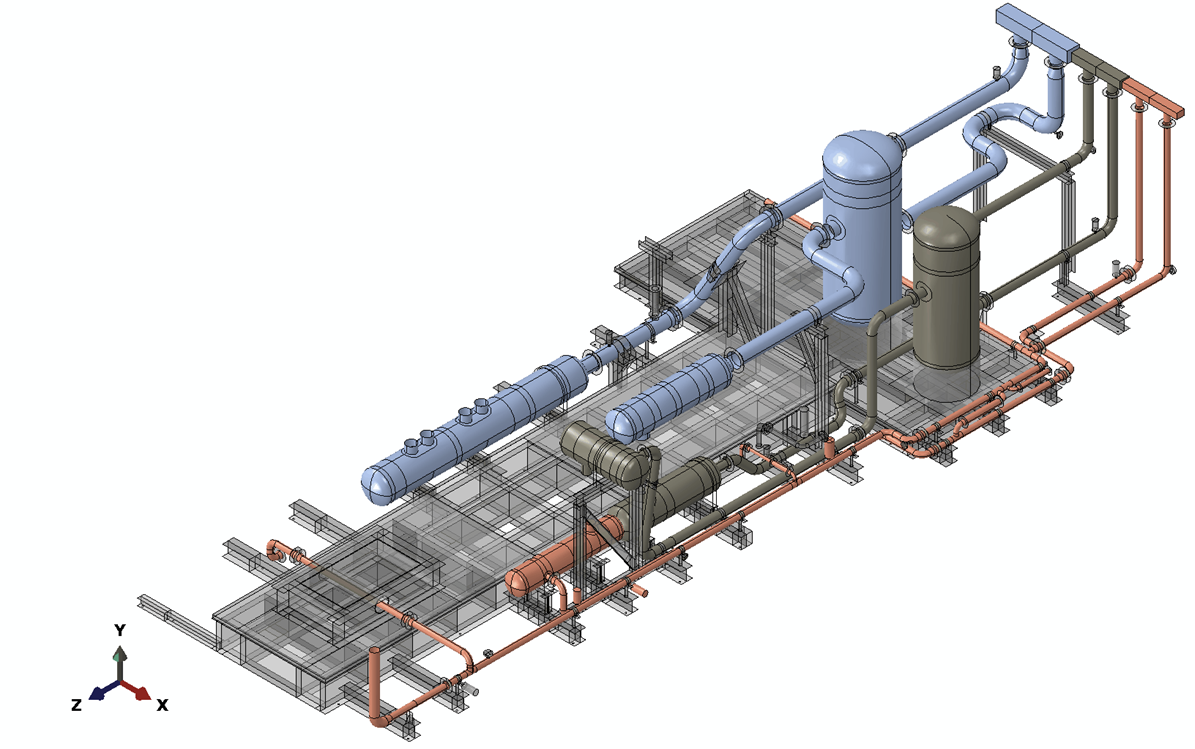

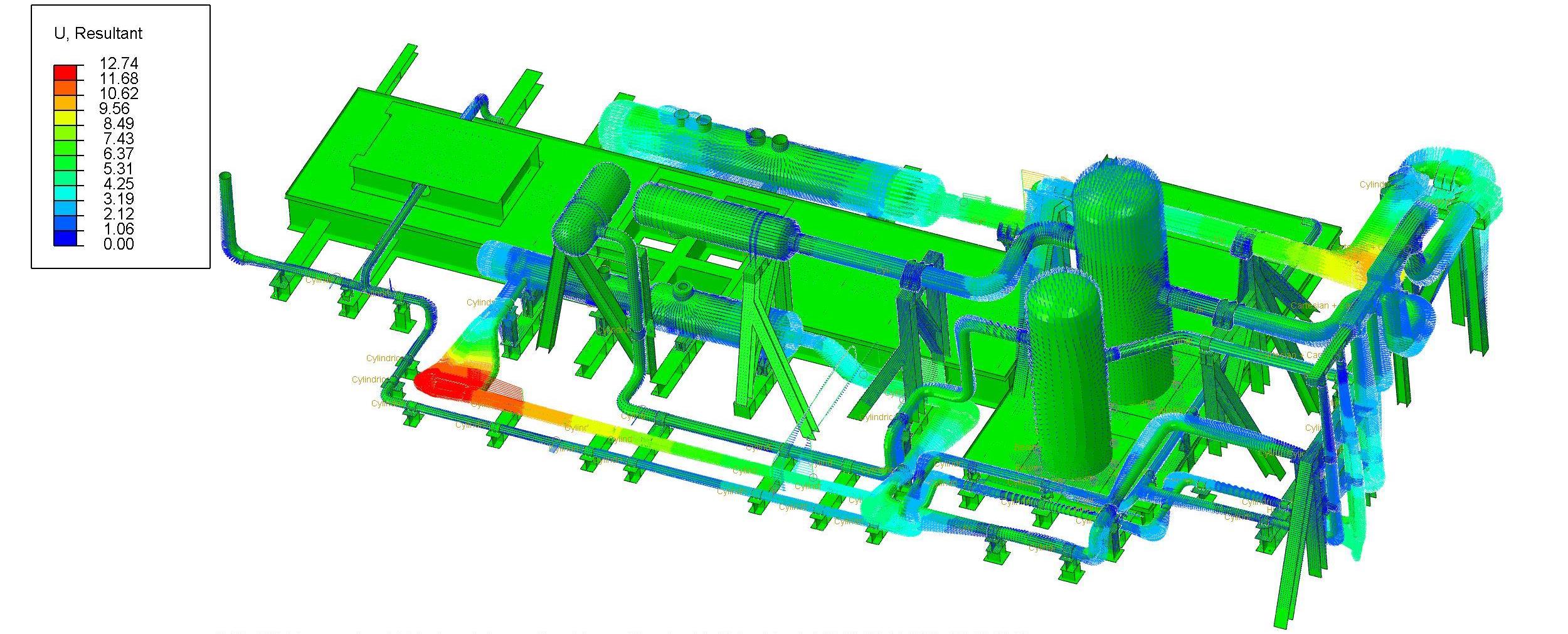

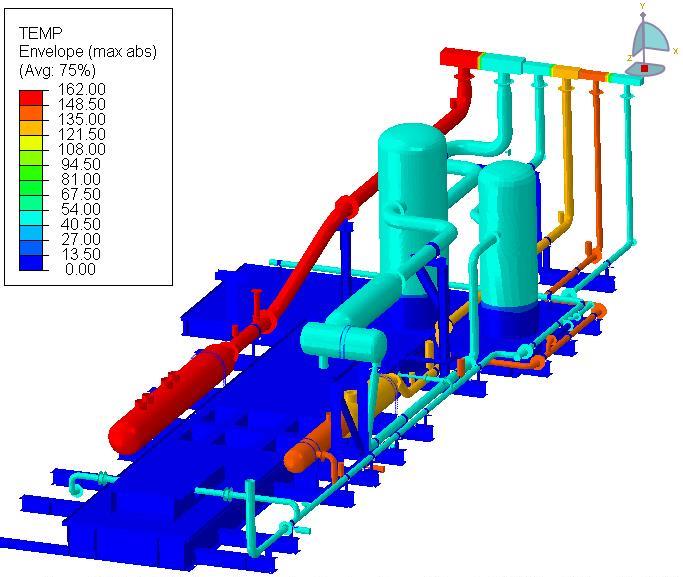

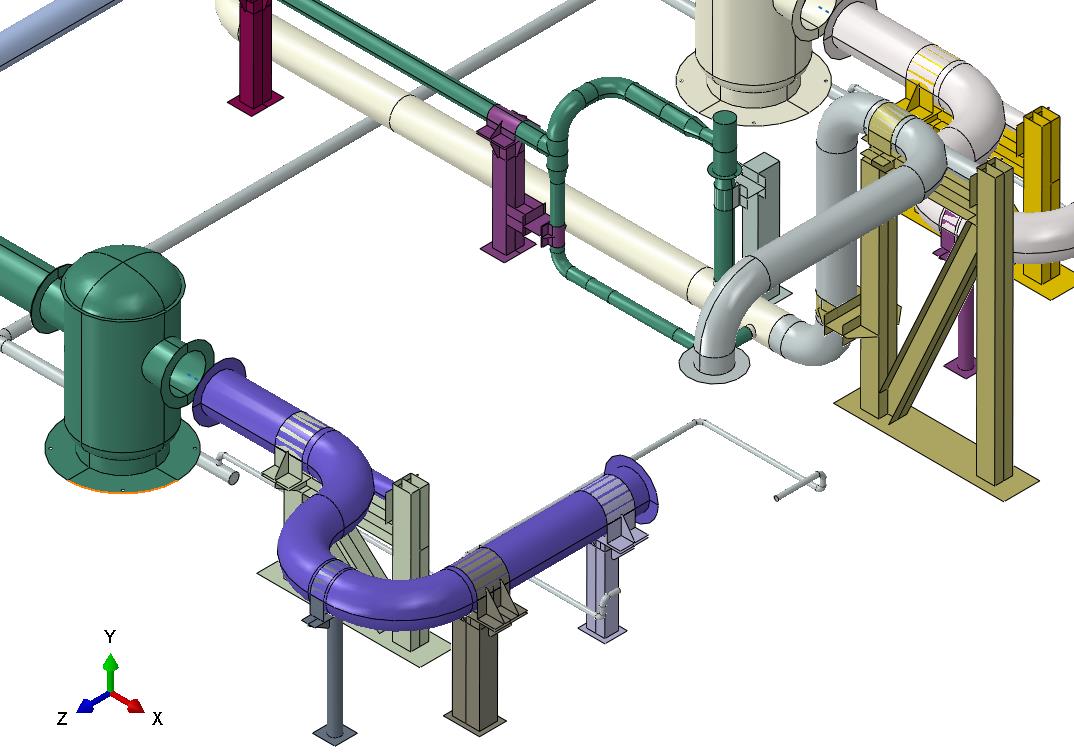

Pumping and compression facilities

We carry out projects both on new or existing facilities, incorporating from the beginning considerations related to dynamic aspects, acoustic structural coupling and resistance to corrosion.

Ver mas All the pumping systems, both rotary or alternative, involve a certain level of mechanical vibration which, if they are not taken into account from the design point, these vibrations can be amplified in the piping systems out of admissible levels or they can feedback the pumping unit in a negative way. In the case of alternative systems, the pulsed outlet pressure can cause mechanical vibrations with acousticâstructural coupling. It is of utmost importance that the system be evaluated as a whole, incorporating to the design the supporting, piping, and equipment; and selecting the manufacturing materials in accordance with the fluids process in order to avoid general corrosion, cracking, corrosion under pressure or erosion corrosion.

Ver Menos

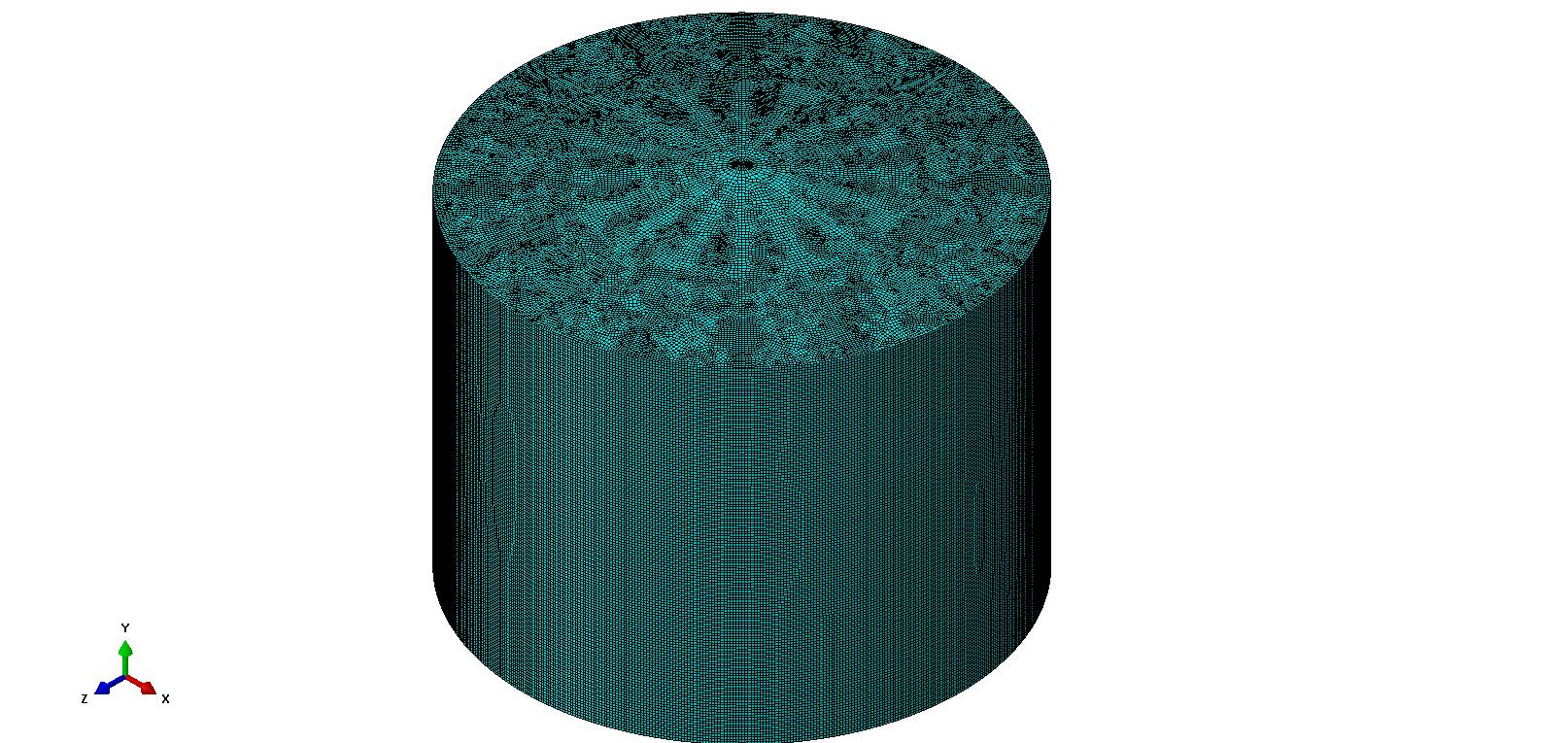

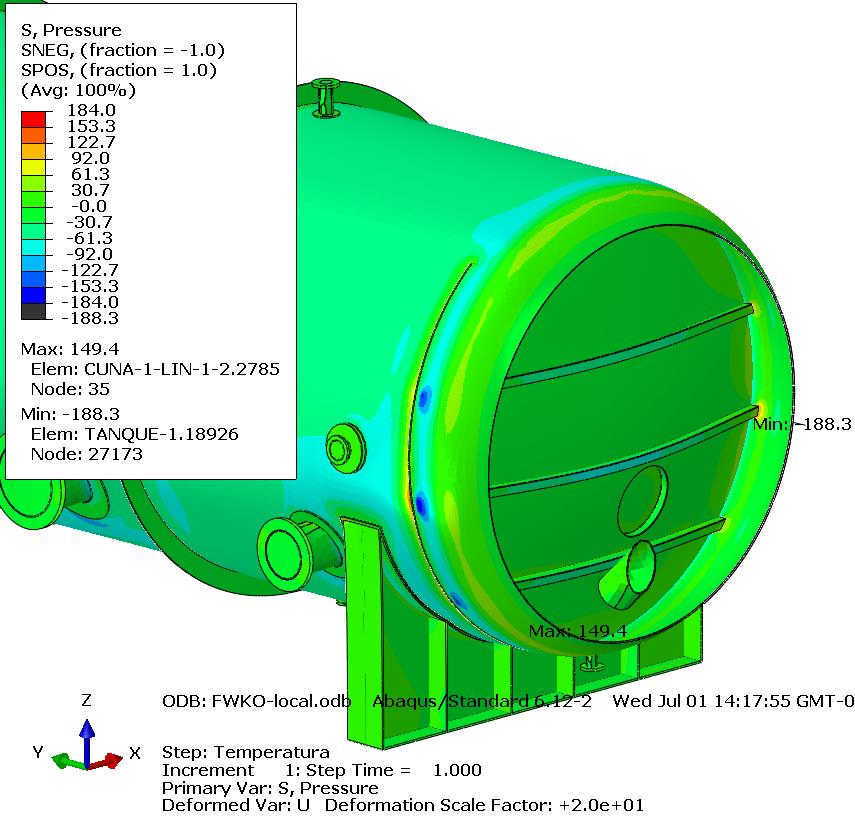

Pressure vessels

Containers for different applications are designed (nuclear, cryogenic, petrochemical, Oil & Gas) under the codes of the industry application (ASME III, ASME VIII). In the case of vessels ASME VIII, div 2, part 5 (calculation design) is preferably used, which result in significant weight reductions in comparison to containers under ASME VIII, div 1.

Ver mas The use of computational tools together with detailed work methodologies, enable to fulfil the highest demands of the application codes, reducing security margins required in its design with its consequential weight reduction. Another additional value results from the vessel and piping joint simulation, to which loads consistent with both systems are applied on connecting flanges. They are in general lower to the simplified solution of assuming the vessel as a fixed point for the stress analysis.

Ver Menos

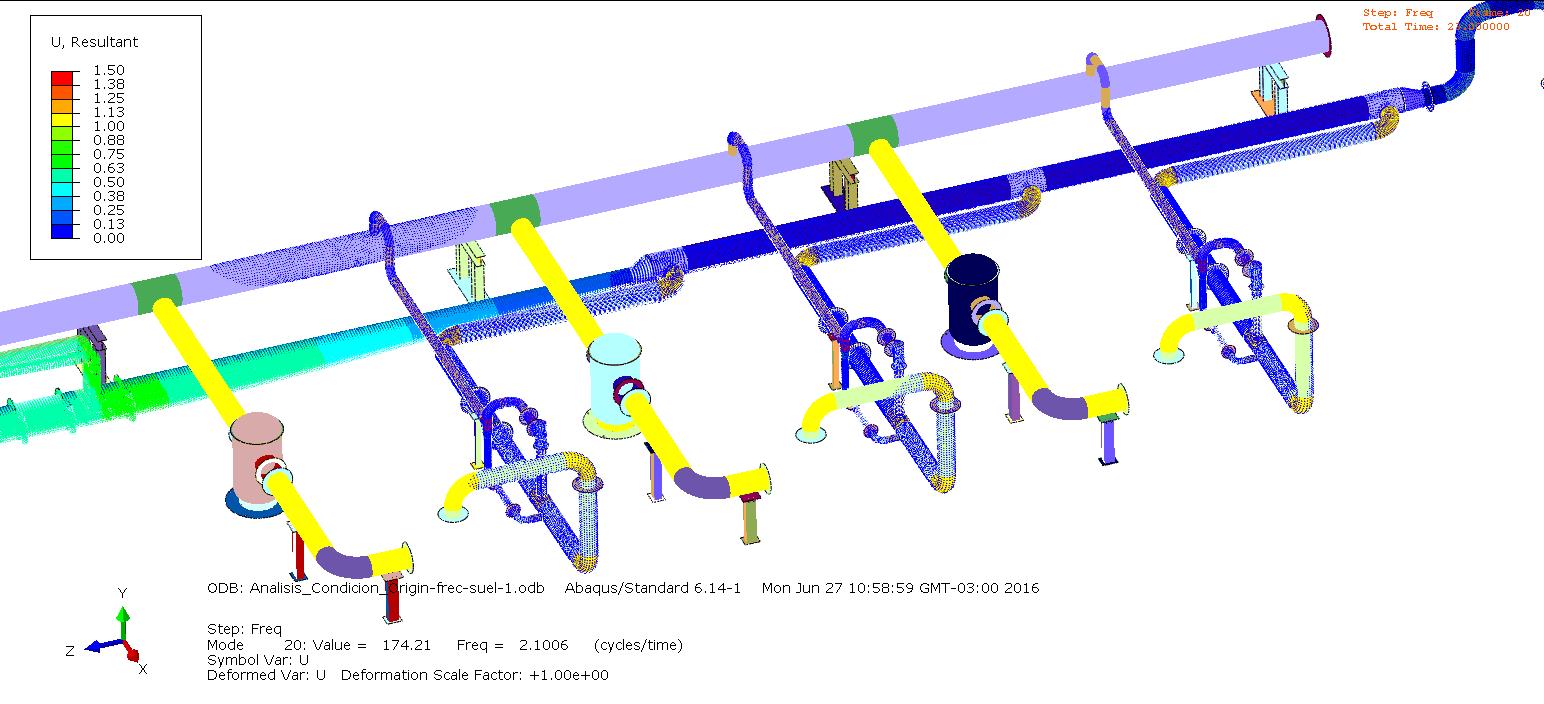

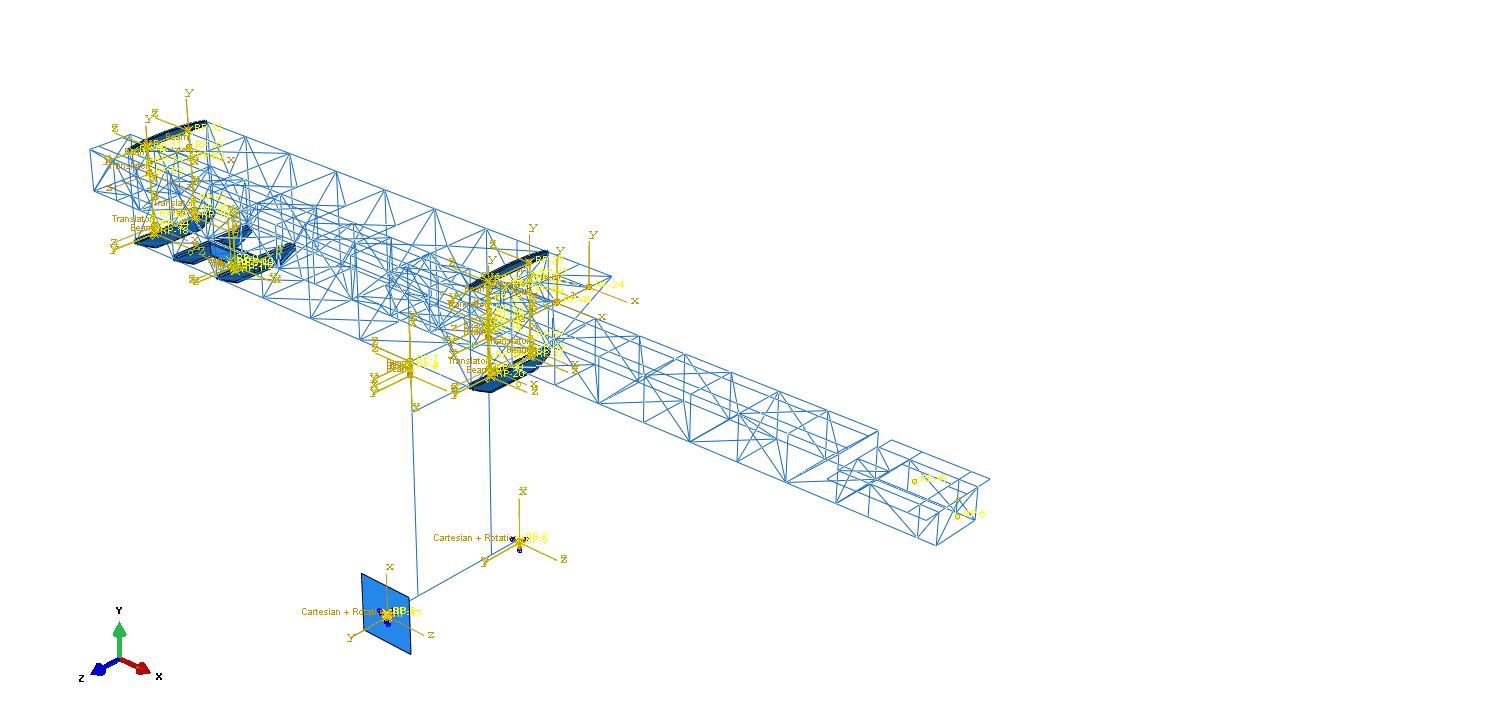

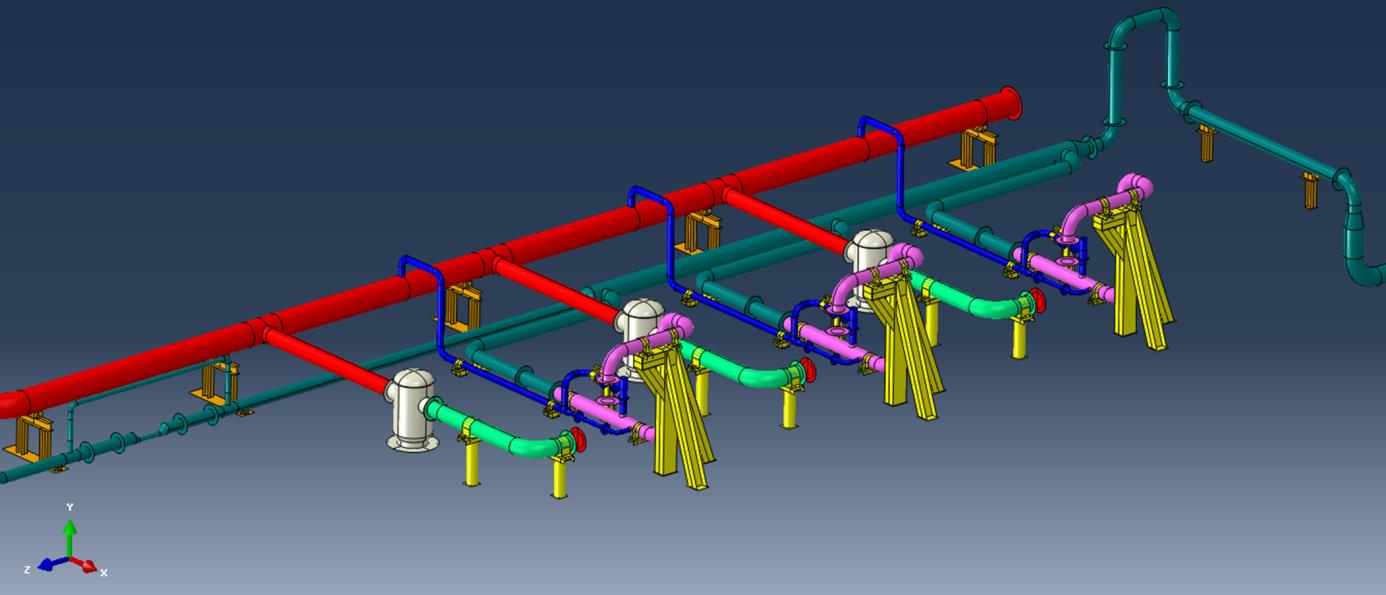

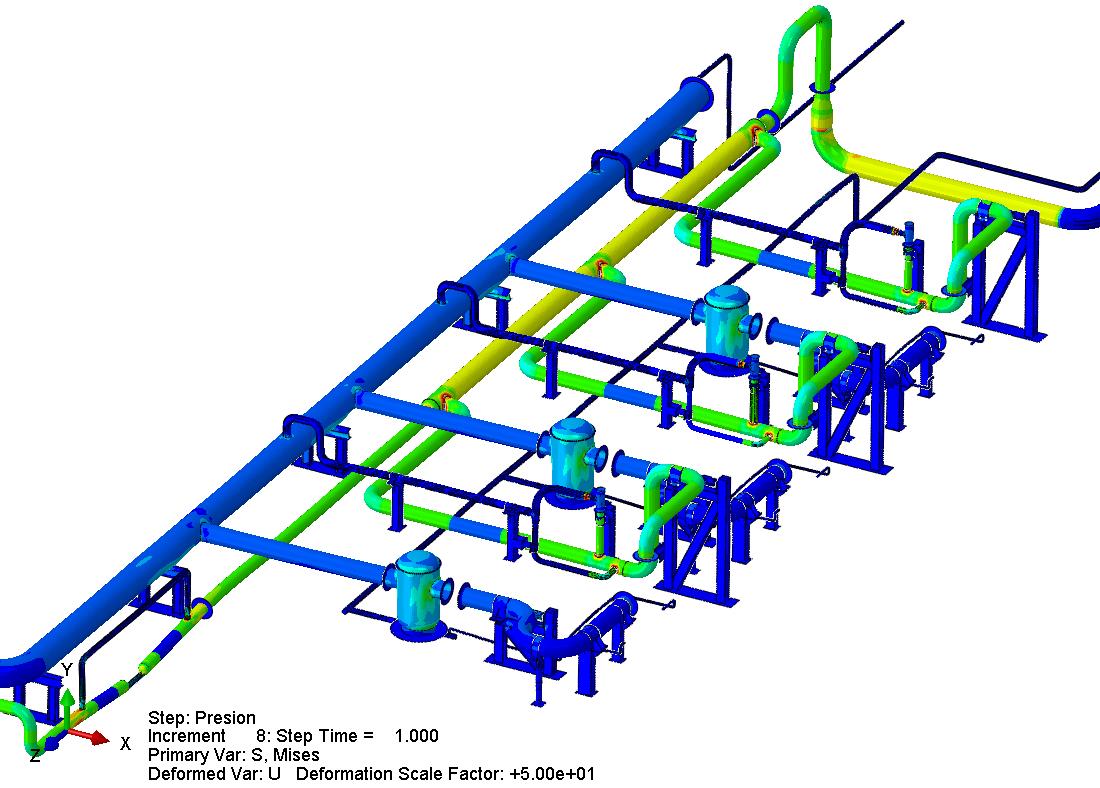

Piping system and stress analysis

We develop piping facilities both in industrial environments (refineries, compression plants, etc.) as well as in field (well lines of conduction, oil pipelines, gas pipe lines). All our projects are normalized under standards such as ASME B31.x or similar ones, and they are presented with their complete engineering and stress analysis under static and dynamic conditions.

Ver mas The piping system project can be carried out both in greenfield and brownfield projects, incorporating technologies such as the laser scan instrument or photometry. In the case of submerged lines, bathymetric data of the sea floor provided by the customer are incorporated to the project. The use of computational tools enables to include in the projects stress analysis in dynamic conditions, acoustic structural coupling, water hammer and realistic soil â structure interactions.

Ver Menos